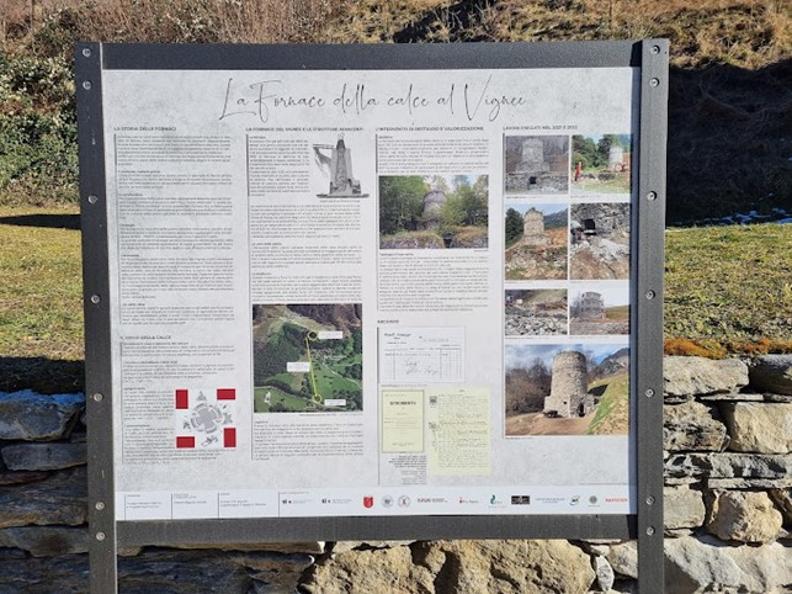

The Vignee kiln

The lime kilns in the upper Blenio Valley are rudimentary structures, but they represent historical evidence of a production activity based on ancient techniques. Lime was obtained from limestone, a sediment of marine origin found in the area.

There were two types of kilns: those with “alternating fire” and those with “continuous fire,” which were more efficient. Production required temperatures between 900 and 1,000°C for about three days, fueled by the burning of large quantities of wood. Processing involved many people in the extraction, transportation, firing and storage of quicklime, which was used mainly in construction, agriculture and tanning of hides.

The Vignee kiln, active until the 1950s, was a pre-industrial continuous-fire plant. A total of 11 meters high, it had a circular tower and base with combustion chambers. The quarry supplied the stones, which were transported via a gravity cable car to the furnace.

Decommissioned for decades, the furnace has been restored since 2021 thanks to the initiative of Enrico Guglielmazzi, with the aim of enhancing it for cultural and educational purposes. The restoration included cleaning the area, reconstructing the missing parts, and consolidating the walls using traditional techniques, returning a valuable historical asset to the community.